| PBT Yarn (DTY) |

| PBT Yarn (POY) |

| PBT Yarn for Sewing Thread |

| T400 like bi-component yarn |

| TEL: +86-519-8231 5188 | |

| FAX: +86-519-8231 5288 | |

| E-mail:michelle.chen@pbtyarn.cn | |

| URL: www.pbtyarn.cn |

Study on cotton woven fabrics with added PBT yarns(2)

As a stretch yarn,PBT yarn can be used in different fabrics and garments.Such as knitwear(PBT yarn is made to core spun yarn or blend yarn first);kniting fabric like sportswear and swimwear;It can also used in woven fabrics(it can directly woven as weft yarn in fabrics,like denim fabrics,medical fabrics and lady's fanshion trousers).Today,we will discuss how it makes woven fabric when used with cotton.

Stretch properties are very important physical properties of woven fabrics,where about 10-30% reversible deformation is required for the clothing comfort.About 2-5% of elastant fibers are normally used into denim 3.3% to 6.6% into woollen fabrics and into cotton shirting fabrics to achieve and adequate stretch ability.PBT has been known since 1968.The molecular weight of a repeated until is 220g/mol and the average polymersization is 100-200.The used material for increasng the extensibility was polyester PET,which has four methylene groups in its structural formula,i.e.two methylene groups more than the most frequently used polyester PET.The melting point of PBT is 225

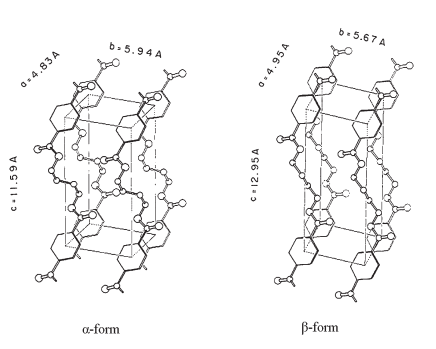

degree and its glass transition temperature is 20-40 degree.Two different crystalline forms are designated as the a-form and ß-forms.The crystal structure of PBT transfrms into ß-form with a hot stretch tretment an into a-form with relaxation.In the ß-form,the chain axis c of the crystal unit is 1.295mm and is longer than in the a-form,,where it equals 1.159nm.Raw PBT yarn poses more of extended ß-form that transform to the a-form that transform to the -form with the thermal treatment,which causes the shrinkage of fabrics dependably on the PBT yarn quantity and fabric structure.

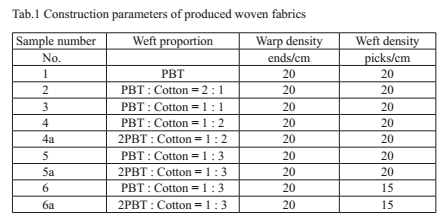

To investigate the changes in the characteristics due to incorporated PBT yarns before n after their thrmal treatment,severl referenced samples were prouces.Woven fabrcs contained 100% cott yarns 17×2 tex as warp,,and the same cotton yarns combined with PBT yarns 7.8 tex f24 as weft in a different proportion.

Cotton as the weft in the following order:2:1;1:1;1:2;1:3.All samples were produced in plain weave with the sae density of warp and weft.Additionally,we produced a few more samples with single PBT weft yarns and lower weft ensity in the proportion of PBT:cotton 1:2 and 1:3,and with 2PBT weft yarns(two PBT 7.8 tex textured yarns inserted as one in the weaving process).In this way,we wanted to know how the increased quantity of PBT yarns in the same and in a more open construction(lower weft density)influences the changes of physical and mechanical characteristics.The labelled sample with their construction parameters are shown in the Tab.1. Sample 1-5 differ in the PBT content(22.5 g/m2,14.7 g/m2,9.9 g/m2,6.7 g/m2,5.2 g/m2),while keeping the weft density the same.Treated samples 1-5 contains 26 g/m2,16.6 g/m2,11.9 g/m2,7.6 g/m2,5.6 g/m2 of PBT in fabric.